Tad stopped by on Monday to help finish off all the Left Wing skins. Also drilled the nut-plates onto the W-919 splice strip that connects the leading edge skin to the fuel tank skin. We also spent some time lightly countersinking(after dimpling) the rear spar on both sides to allow the dimples in the skin to fit better.

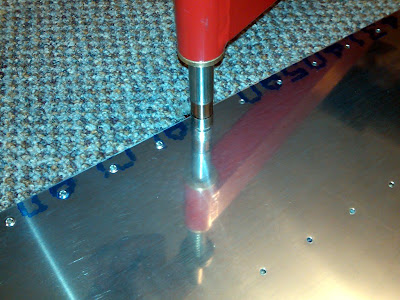

Over the last couple of days I've spent a couple of hours countersinking the #40 holes on the main spar to accept the skin dimples. With the main spar being a lot thicker than the rear spar there was no dimpling necessary... just full countersinks with the micro-stop on the drill.

They are all done now:)